Solutions

Skyconcrete Indoor. The “nuvolato” effect, with low thickness and continuous surface

Skysense. The light polished effect, low thickness and continuous surface, tone-on-tone

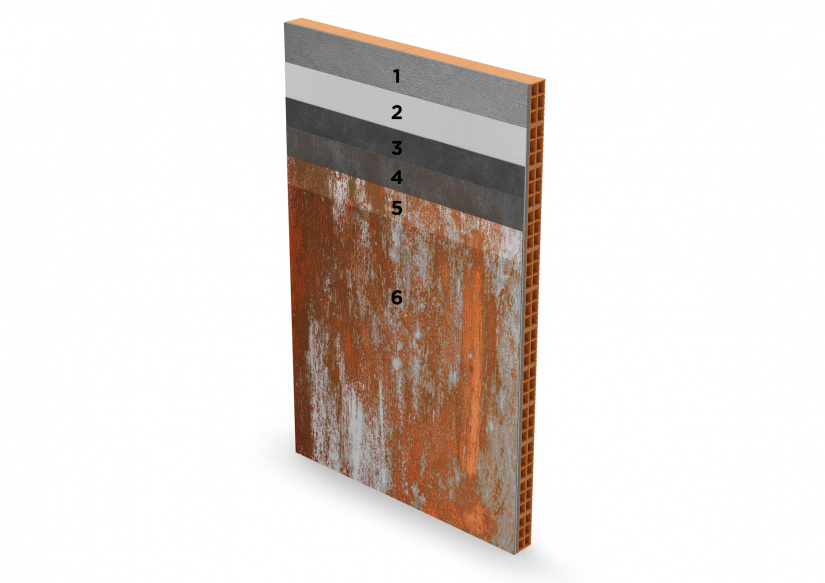

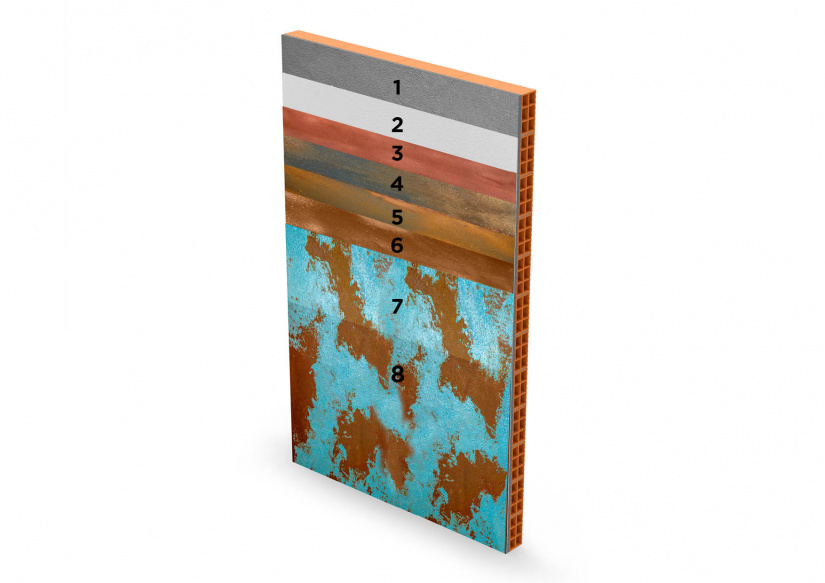

Oxydecor®. The decorative coatings that recreate the corten steel, galvanized and copper effects

Skyconcrete Outdoor. The “nuvolato” effect, with low thickness and continuous surface

Plam Spray. Refresh concrete surfaces with a wide range of stencils and textures

Plam Rock. Artificial rocks and scenographic effects for gardens, amusement parks and swimming pools

Skygrip. The low-thickness material effect for outdoor use

Deco Nuvolato Grip. The non-slip cloudy effect for outdoors

© 2026 - Isoplam Srl - All rights reserved

Via Enrico Mattei, 4

31010 Maser (TV) Italy

Tel. +39 0423 925023

Cel. +39 3275653160

P.IVA 02432450266

Company subject to the management and coordination of MDF Holding

Newsletter Isoplam

Do you want to stay updated on Isoplam and receive all the news on events and useful tips?